Challenges:

Expand the set of monitored parameters (e.g., fuel flow, pressure, temperature, starter/generator voltage and current, and contact condition) on the existing test stand while maintaining the ability to perform periodic tests on the turbine during the conversion phase from the old system to the new one.

Solution:

With the NI LabVIEW system development software, NICompactDAQ data acquisition system, USB to RS485 converter and a set of high precision sensors and transducers, we provide the required parameters for the raw data acquisition system of the test bench, providing the engine to the customer without interruption.

Profile:

Since 1953, Aerostar SA has been a major supplier of products, services and support to several air and ground forces and civil aviation markets (industrial and operator) worldwide. Its main area of activity is the overhaul of fighter jet turbojet engines and it has repaired more than 6,000 units.

Our original turbojet engine test stand was 40 years old, but the building and heavy equipment were still in good condition. The data monitoring/recording equipment was outdated and many parameters were recorded manually. For example, highly dynamic parameters were recorded on data logger (FDR) type film, and fuel flow measurements were based on weight measurement methods (e.g. measuring the time it took for the engine to consume a certain amount of fuel) and were performed multiple times during engine operation.

When gas consumption is not a major problem, we make extensive use of this complex device. The total fuel consumption was measured in tens of tons per engine. Today, given the rise in fuel prices, any percentage reduction in fuel consumption means a significant reduction in costs. Reduced fuel consumption also means reduced CO2 emissions and therefore benefits the country

By the end of the 1990s, the failure and obsolescence of FDR-type chip recorders forced us to replace them with new acquisition systems with:

-New sensors for pressure, temperature, vibration, speed and thrust

-Commercial off-the-shelf (COTS) data acquisition system with 8 modules to acquire highly dynamic signals from new transducers

-Pentium PC-based control computer with Visual Basic data acquisition and database software, and MATLAB® 4.2 application for graphics

In the past few years, the aviation market has faced new challenges in the global economic climate. New requirements to be met for testing turbojet engines include: reduction of total fuel consumption for engine commissioning, reduction of CO2 emissions, reduction of noise pollution, improved accuracy of process monitoring, automatic calculation of reporting parameters, remote access to the test process and video monitoring of the engine in all states.

Based on the existing facilities and the new requirements, we faced several challenges. We had to maintain high accuracy in the previous implementation so that the new installation would not interfere with the operation of the existing system. We also had to continue working through the transition phase so as not to interrupt the regular testing of turbojet engines by our current customers. Finally, we had to integrate existing data into the new database in order to take advantage of valuable existing data and expertise.

Considering the above requirements and challenges, we have developed a new data acquisition system. We added new components to the existing ones to complement the functionality and meet our requirements.

Hardware Implementation:

At the heart of the new addition is the NI CompactDAQ system, which contains an NI cDAQ-9172 8-module chassis, as well as the following appropriate modules for signal acquisition from sensors:

-Three NI 9203 8-channel, ±20 mA, 16-bit analog input modules

-One NI 9221 8-channel, 12-bit analog input module

-One NI 9422 8-channel, 24 V drain/source, channel-to-channel isolated digital input module

-Three spare modules

The key component is the Coriolis mass flow meter. With this high precision transducer, instantaneous flow measurements are possible, thus eliminating the need for the very difficult gravimetric method. By permanently measuring the fuel rate online, we save hundreds of kilograms of fuel during each engine test. the Coriolis flowmeter electrical interface is RS485 and the communication protocol is MODBUS RTU.

Due to security restrictions, employees were unable to enter the motor room to inspect and adjust the motor while it was running at high speed. Therefore, a video surveillance system was installed in the engine room in order to visually inspect the various areas of the running engine. The video monitoring system consists of a PTZ camera connected to a PTZ remote controller and a PC with a video capture board.

Each activity is controlled by a Pentium 4 dual-core PC that contains two LCD widescreen monitors, keyboard, mouse, color printer, LAN adapter, and TV tuner. The system collects data from the NI CompactDAQ chassis via USB. It reads the fuel mass flow rate and total fuel consumption from the Coriolis flowmeter via USB and transmits it to an RS485 smart transformer. It uses an RS232 line to connect to an existing COTS data acquisition system with a clever CSMA/CD arrangement that emulates Ethernet and parallels an older Pentium PC still used as a backup. Finally, the video surveillance images are displayed and recorded (see Figure 1 and Figure 2).

Figure 1: Engine to be tested using the new NI CompactDAQ-based data acquisition system

Figure 2: New NI CompactDAQ-based Data Acquisition System Control Panel

Using traditional instruments to achieve this level of functionality would be extremely costly. By implementing NI solutions through PXI and LabVIEW, we have helped us achieve our goals and cut the cost in half.

Software Implementation:

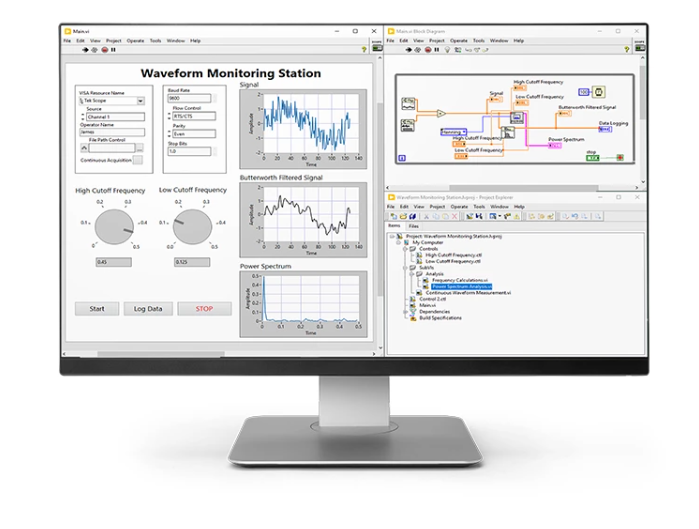

To develop the software, we took full advantage of the parallel processing capabilities inherent in LabVIEW and the multi-core architecture of the new PC. The application performs the following tasks:

-Acquire data for NI CompactDAQ chassis and modules using NI-DAQmx drivers

-Communicate with legacy COTS data acquisition systems and Coriolis flow meters, supporting the use of the NI MODBUS library

-Display values on the numeric and virtual dials of the front panel display controls, and display graph/graph plots

-Automatic calculation of indirect parameters

-Automatic archiving of data in database

-printing data using printer (hard copy)

-Help with remote operation and monitoring using LabVIEW Web server

Figure 3 shows the control panel of the main Virtual Instrument (VI).

During the software development and hardware integration process, the NI Romania support team provided valuable advice in real time via phone and email. They shared best practices for configuring the system and continuously transferring data from the data acquisition module.

Conclusion

The analysis of the economic impact of the new functionality revealed several positive factors during the commissioning of the turbojet engine. It reduced the time for fuel flow measurements (Coriolis measurements instead of gravimetric measurements). It also reduces engine run time by using instant DAQ logging instead of manual readings, and supports the use of real-time graphics and video monitoring/checking for troubleshooting and engine operation adjustments in all states, also reducing engine tuning time. These positive factors help reduce fuel consumption and CO2 emissions