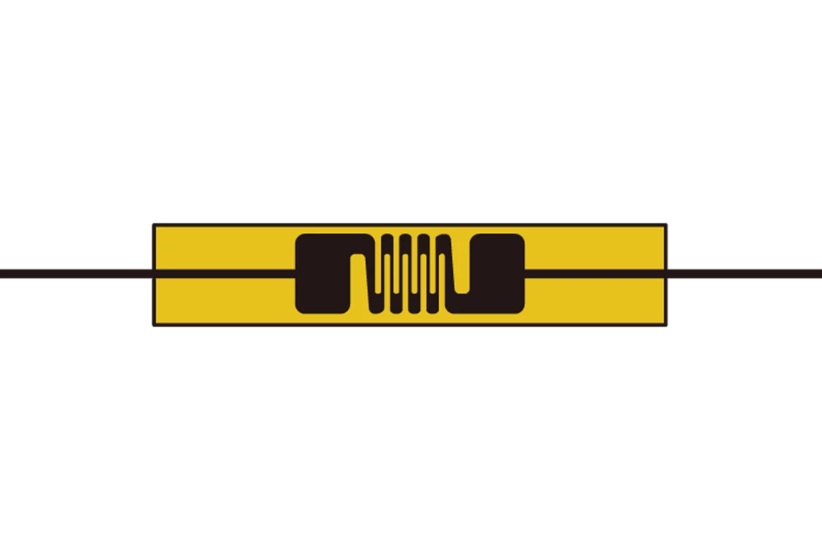

Strain Gauges are developed to measure strain on an object. Strain gauges are made of electrical wire or photo edged foil resistance material and are attached to the object. When external force is applied to its structure it creates a physical deformation of the material and creates change in resistance in the attached strain gauges.

Strain Gauges are designed to handle every possible application and are often used for research & development, sensor manufacturing and custom made applications.

We are happy to help you choose the most suitable acceleration sensor or measurement solution.

Fill out our contact form or contact us directly: you can find the phone number and email address of your nearest location on our location page.

- Small error, generally less than 1%;

- Small size and light weight.

- Large measuring range, from elastic deformation to plastic deformation (1-2%), up to 20%;

- Can measure both static and fast alternating stresses;

- All the advantages of electrical measurements, such as easy transmission, recording and processing of the results;

- Can work in a variety of harsh environments. Such as from the cosmic vacuum to thousands of atmospheric pressure; from near absolute zero temperature to nearly 1000 ℃ high temperature; centrifugal acceleration up to hundreds of thousands of "g"; in the vibration, magnetic field, radioactivity, chemical corrosion and other conditions, as long as appropriate measures can also work reliably;

- Low price, variety, easy to choose and use in large quantities.

Automotive industry&Racing

Construction

Biomechanical testing

Aerospace

Industrial robot

Sports & Recreation