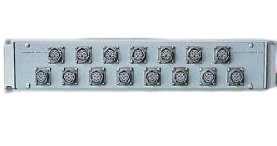

9216

Product Description

The 9216 series NetScanner pneumatic px scanner w ptp integrates 16 silicon piezoresistive pressure sensors of any pressure range with the latest microprocessor technology in a compact, ruggedized package. Each field replaceable pressure sensor incorporates a temperature sensor and EEPROM for storage of calibration data along with sensor identification information such as pressure range, factory calibration date and user-managed last or next calibration date. The microprocessor uses the data from the EEPROM to correct for sensor offset, span, linearity and thermal errors. The microprocessor’s digital temperature compensation algorithm reduces sensor thermal errors by a factor of ten or more over conventional sensor compensation. The microprocessor also controls the actuation of an integral manifold to execute on-line zero or span calibrations upon request. This capability virtually eliminates sensor offset drift error and provides system accuracy errors less than ±0.05% FS (Full Scale). The 9216 can sample using up to three concurrent scan lists at continuous rates up to 500 measurements per channel per second in engineering units with time stamps. Pressure data in engineering units is output through an auto-negotiating 10 or 100 Mbit Ethernet interface supporting both TCP and UDP protocols. The 9216 data output optionally includes data time stamps derived from either the 9216 internal real time clock, NTP clock or an IEEE 1588-2008 Precision Time Protocol (PTPv2) grand master clock. The scanner is supplied with comprehensive software called NUSS for PC compatible computers. Firmware upgrades are available at no charge via our website and can be downloaded to the scanner over the 9216 Ethernet interface using NUSS. The Model 9216 intelligent pnuematic pressure scanner is one component of the NetScanner system. Multiple NetScanner components measuring a wide variety of parameters and sharing the same command set can be networked to form a distributed intelligent data acquisition system.

Key Features

+0.05% FS System Accuracy

EU Throughput Rates of 500 Hz

IP66 Rated Enclosure

IEEE 1588-2008 PTPv2 & NTP disciplined clock

Auto start capability

Applications

Turbomachinery Test Stands

Wind Tunnel Wall Pressure Measurements

| PARAMETER | 9216 | Unit | COMMENTS |

| PNEUMATICS | |||

| Pressure Range | ±10 ±20 | In WC | |

| ±1 +50 +375 ±2.5 +60 +500 ±5 +100 +650 ±10 +125 +750 ±15 +150 +850 +30 +200 +1100 +35 +250 +45 +300 | psi | Ranges ≤ 10 psi are calibrated over the range of –FS to +FS pressure Ranges > 10 psi and < 100 psi are calibrated over the range of -12 psi to +FS pressure ranges ≥ 100 psi are unidirectional only | |

| Number of Pressure Inputs | 16 | available in combined ranges | |

| Media | Dry | non-corrosive gas | |

| STATIC PERFORMANCE | |||

| Measurement Resolution | ±0.003 | % FS | |

Static Accuracy After Rezero | ±0.05 ±0.15 | % FS | range > 2.5 psi range ≤2.5 psi |

| Measurement Rate | 500 | meas/ch/sec | engineering units |

| ELECTRICAL | |||

| Input Voltage | 18 - 36 | VDC | unregulated |

| Input Current | 225 | mA | maximum @ 24VDC |

| COMMUNICATION | |||

| Communication | 10/100 Base-T | auto negotiating, half duplex/full duplex | |

| Protocol | TCP and UDP | static or dynamic IP assignment | |

| Time Protocol | PTPv2 (IEEE 1588-2008) or NTP | external master clock or server required | |

| ENVIRONMENTAL/PHYSICAL | |||

| Calibrated Temp Range | |||

| Standard | 0 to 60 | ºC | |

| Optional | -30 to 60 | ºC | |

| Operating Temp Range | |||

| Standard | -20 to 70 | ºC | up to 95% non-condensing humidity |

| Optional | -30 to 80 | ºC | |

| Storage Temp | -30 to 80 | ºC | |

| Size | 9.50 x 3.50 x 3.54 | inches | L x W x H |

| Weight | 6.5 | lb | |