Pressure scanners and associated pressure measurement data systems allow engineers and scientists access to large amounts of pressure measurement data for critical flight test studies. The NetScanner Series 9216 pressure scanning valve provides an accurate and reliable pressure scanning solution for the diesel engine test bench pressure testing market.

Ⅰ、Overall overview

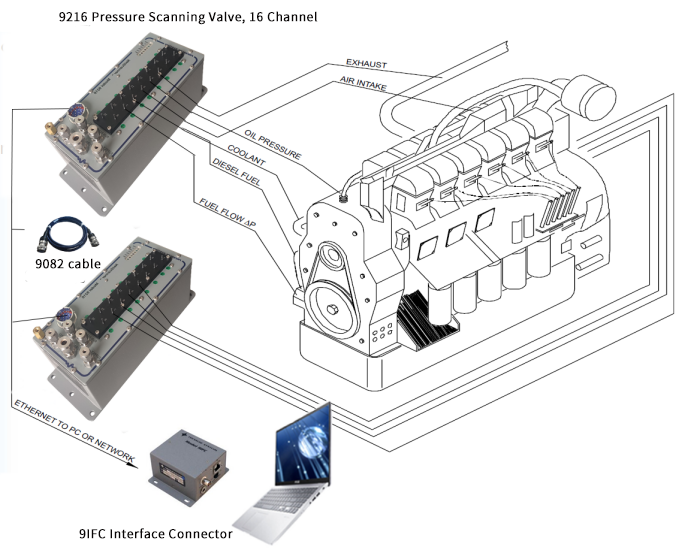

The NetScanner Series 9216 pressure scan valve is ideal for diesel engine development and production test units. The 16-channel pressure module is robust and can withstand extreme temperatures, shocks and vibrations, with an optional range and splash resistance. 1/16, 1/8 or 1/4 inch compression joint pressure input, can be selected according to the working condition. Thus they are suitable for installation in the test cell, and the 9216 modules use TCP/IP protocol for Ethernet communication. This digital approach eliminates many analog wires and signal conditioners as well as possible noise problems.

Ⅱ、Pressure measurement

The NetScanner Series 9216 pressure scan valve is capable of recording most of the pressure measurements that must be performed during a pressure test. Our module can measure diesel engine leading edge pressure distribution, engine compartment inlet deformation pressure and gas turbine pressure measurement. Pressure scanning valve with 16 pressure input channels. These pressure scanners can be placed outside the engine or in the engine compartment to reduce tubing length. The pressure scanning valve contains an internal pneumatic valve to allow the user to:

1. Pressure measurement;

2. Zero calibration;

3. Multi-point calibration (pre-flight or in-flight);

4. Purge operation (cleaning condensate and other pollutants in the input line).

NetScanner 9216 pressure scanning valve

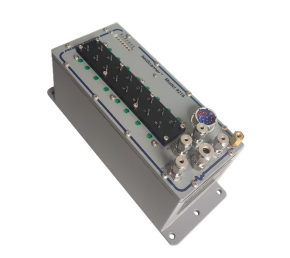

The Model 9216 Smart Pressure Scanner integrates 16 silicon piezoresistive pressure sensors with the latest microprocessor technology for any pressure range in a compact, rugged package. Each field replaceable pressure sensor includes a temperature sensor and EEPROM to store calibration data as well as sensor identification information such as pressure range, factory calibration date, and last or next calibration date managed by the user. The microprocessor uses the data from the EEPROM to correct for sensor offset, range, linearity, and thermal errors. The microprocessor's digital temperature compensation algorithm can reduce the sensor thermal error compensated by traditional sensors by a factor of 10 or more. The microprocessor also controls the actuation of the overall manifold to calibrate the zero or range online upon request. This function actually eliminates the sensor offset drift error so that the system accuracy error is less than ±0.05% FS. Pressure data within the engineering unit are output through an automatically negotiated 10 or 100 Mbit Ethernet interface that supports TCP and UDP protocols. Pressure measurements range from 10 "H2O to 1100 PSI.

Ⅲ、Application examples

1. NetScanner series 9216 type pressure scanning valve can meet the diesel engine test bench test pressure measurement requirements. Type 9216 intelligent pressure scanning valve supports 16 pressure channels; The accuracy of the system was ±0.05% FS. The throughput rate of each channel was 500 Hz. The operating temperature of the host is -20 to 70°C, and the storage temperature is -30 to 80°C; Automatically set 10/100 Base-T Ethernet interface; The protection level is IP66; Automatic start function. The connection required for system operation is simple, the user can use the 9IFC interface connector power supply, the module is connected to the 9216 via 9082 cable, providing convenience for power regulation, hardware triggers and Ethernet communication.