The Challenge:

Test audio/video circuitry and static parameters of printed circuit boards (PCBs) on the production line while avoiding high engineering time and costs when the target product changes.

Solution:

Cut test system costs in half by developing flexible, easy-to-use functional circuit test (FCT) systems using PXI and NILabVIEW.

Mass-produced PCBs must pass in-circuit testing (ICT) and FCT before they can leave the factory. ICT is usually the first test step, where every electronic component is tested and every short and open circuit fault of every circuit is checked in-circuit. Most PCBs use firmware to control the integrated circuit board.

After ICT, we can determine the quality of the electronic components and parts of the PCB under discussion, but we cannot determine if the entire circuit is working properly. The test engineer must build a simulated circuit environment in order to perform FCT at the test points (TP) on the IC board. FCT simulates the functions of the finished product and tests whether these functions are completed.

In most cases, FCT systems on the production line test only one type of PCB.Such systems are typically developed by designing the control board and connecting all I/O ports to the test fixture. The test engineer then builds the firmware for the control board to set up the finished product's simulated operating environment to test the voltages and currents and the corresponding sequential controls. After testing is complete and the product is shipped, the FCT system is often put on hold and additional engineering resources are required to plate, program, and wire the FCT system developed for the different PCBs. In addition, more complex features are constantly being added to the PCB, which makes some functional tests more difficult to build.

Honeywell wanted to avoid the duplication of effort that is often the result of this development process and identify a lower cost, more flexible solution that could address the FCT and increasingly complex PCB functionality of multiple PCB products.

Using the PXI hardware platform and LabVIEW software, Honeywell focused on creating a complete set of integrated automated functional tests to test audio, video and various signals such as voltage, current and digital.

Functional Requirements:

-Multiple high-speed bi-directional I/Os to monitor fixture status, implement communication protocols such as I2C, and achieve sequential control of most chips on the PCB

-Multiple analog input and output channels to generate waveform signals as analog inputs to the PCB

-Multi-channel programmable switch matrix for switch control

-RS232, RS485 serial card to realize serial communication

-Programmable multimeters for voltage and current measurements

-Oscilloscopes for frequency measurement and waveform acquisition

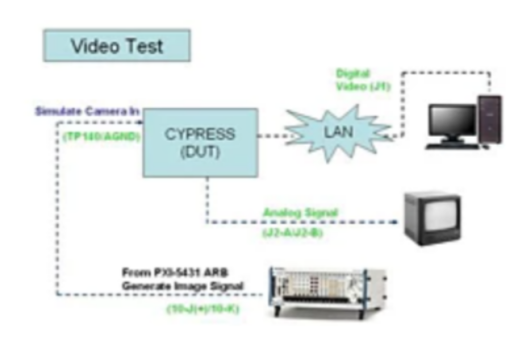

-Video generation, acquisition and analysis

-Audio acquisition and analysis

-Programmable power supply modules

-Unified programming environment

Using traditional instruments to achieve this level of functionality would be extremely costly. By implementing NI solutions through PXI and LabVIEW, we have helped us achieve our goals and cut the cost in half.

System Architecture:

In the past, a simple FCT system required a test fixture. Different functional requirements required the design of various control circuits which were connected to the dial base. In addition, the firmware of the microcontroller needed to be programmed. Test results were displayed on an LCD screen; for more complex systems, PC software was developed to control the serial communication between the microcontroller and the PC. With PXI, Honeywell's solution freed up the time of the test engineers, who avoided duplication of effort in plate making, programming, and wiring.

The advantages of the PXI and LabVIEW solution include:

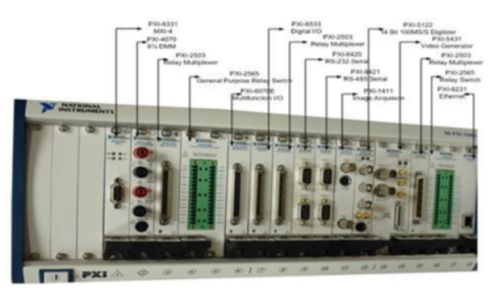

Unified allocation of hardware resources: With the 18-slot NIPXI-10453U chassis, we can easily allocate hardware resources based on the slot numbers of the various cards. By using a Small Computer System Interface (SCSI) cable, signals are connected to the side of the device called the "interface receiver".

Test Fixture Unified Interface: A fixed size Neilsbed dock sits on top of the "Interface Receiver" and the TP signal is connected to the PXI acquisition module through the dock interface.

Programmable Power Control: The programmable power module can be controlled using GPIB to generate a stable power supply for any voltage and current within the operating range of the various PCBs.

Unified Control Software Interface: LabVIEW provides a unified user interface and modular programming of each PXI module, thus reducing programming time.

Rational cabinet layout: PXI allows for a simple and compact layout of all instruments in the system. We implemented a 2x1.2x1.4m cabinet with five levels (Figure 1).

Fig. 1 Cabinet

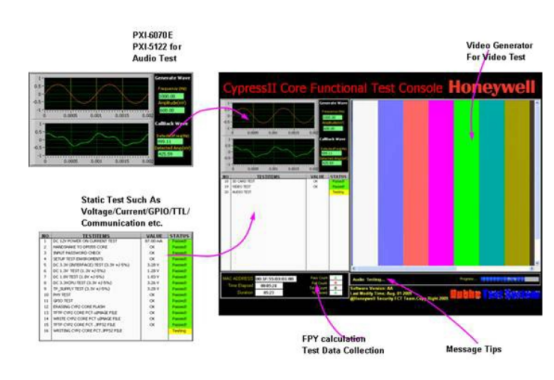

Low Cost Audio Testing

Audio testing is critical for electronic security products. The audio quality of many products must meet high national standards. the NIPXI-4461 data acquisition module can completely replace more expensive audio analyzers. the PXI-4461 combined with NI software can acquire and analyze audio signals and emulate a sinusoidal signal as an input source to the PCB, and measure the frequency and amplitude of the audio output signal. the PXI system is shown in Figure 3.

Fig.2.Schematic diagram of video detection

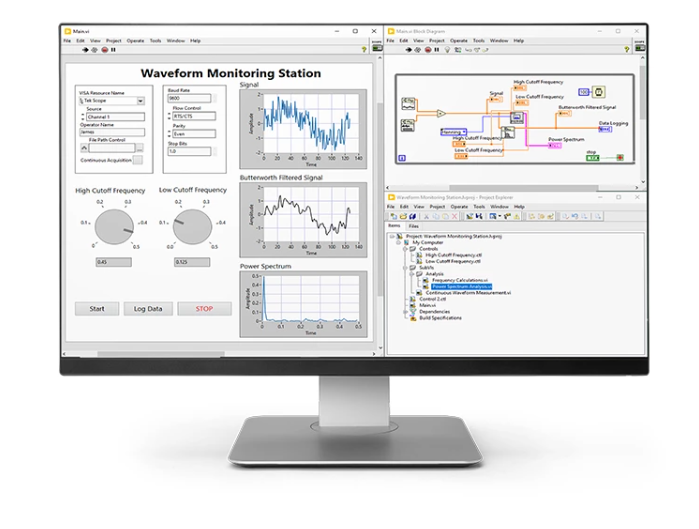

Figure 3. PXI Test Platform

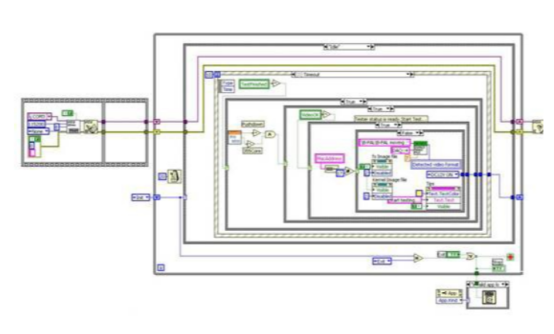

System Software Design

The efficiency of an FCT system can only be fully realized by combining hardware with easy-to-use software. seamless integration of LabVIEW with PXI is an obvious choice.

In addition, programming in LabVIEW allows us to use various protocols such as GPIB, I2C, Modbus and TCT/IP. Furthermore, by using the Virtual Instrumentation Software Architecture (VISA) library, we can quickly and seamlessly implement data processing and interactive displays.

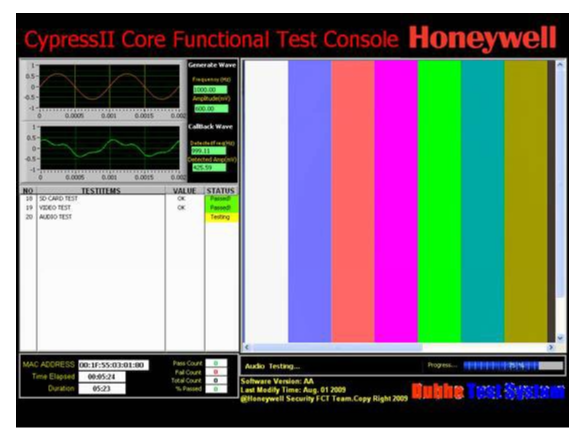

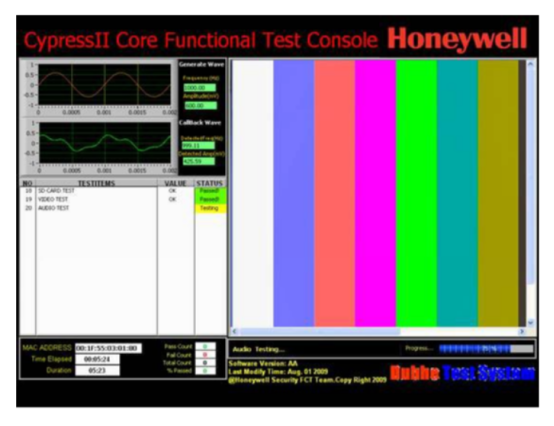

We divided the front panel of the software into five parts, including the static parameter display window, the audio test window, the video test window, the pass percentage display window, and the information window.

Figure 4. Software control interface

Figure 5. Main interface

Figure 6. Block diagram of the main program

Results

By using a variety of PXI products and LabVIEW software to implement the FCT system, Honeywell met all test function requirements and achieved accurate and fast hardware control and high-speed acquisition. Despite the complex architecture of the FCT system and the many inputs and outputs, the PXI system has the advantage of being very powerful and easy to modify. We can implement a variety of FCT tests on the PCB without the need to change test hardware frequently. When a new product is ready for testing, we simply change the test fixture, connect the test fixture pins according to the PXI system's hardware source, and modify the test software accordingly. the LabVIEW graphical interface and ease of use make it simple for the test operator to activate the test fixture, follow the host's graphical prompts, and lift the handle when the test is complete.

By using PXI and LabVIEW to develop our new FCT system, we have significantly reduced repetitive engineering efforts and can share resources more easily. We have successfully applied the solution to our production line, resulting in stable and reliable PCB testing. When new products are released, research engineers only need to add new test fixtures, assign probes, connect signals, and modify software. the NI solution greatly reduces the workload of Honeywell's test engineers and cuts costs without sacrificing test quality or functionality.