Pressure scanners and associated pressure measurement data systems allow engineers and scientists access to large amounts of pressure measurement data for critical flight test studies.

NetScanner pressure scanning valves and mini ESP pressure scanning valves combined with Initium data systems provide accurate and reliable pressure scanning solutions for the flight test market.

Ⅰ、Overall overview

All aerospace products must undergo extensive testing to demonstrate design effectiveness before commencing production. Testing begins with computer-generated drawings, followed by wind tunnel and ground testing, and finally all products must be tested under flight conditions. The instruments used to monitor and record test data must not only be robust and compact, but must also be able to withstand extreme temperatures, shocks and vibrations. TE manufactures measurement products and pressure data acquisition systems that are ideally suited for flight test measurements, and all scanvalve systems for flight test applications have been tested for high vibration and impact.

Ⅱ、Pressure measurement

Both the NetScanner Series 9216 pressure scanner and the small ESP pressure scanner are capable of recording most of the pressure measurements that must be taken during flight testing. Our module can measure the wing leading edge pressure distribution, engine compartment inlet deformation pressure and gas turbine pressure measurement. 16,32 and 64 Pressure scan valves for pressure input channels. These pressure scanners can be placed in the cabin, wing, or engine engine compartment to reduce tracheal length. The pressure scanning valve contains an internal pneumatic valve to allow the user to:

1. Pressure measurement;

2. Zero calibration;

3. Multi-point calibration (pre-flight or in-flight);

4. Purge operation (cleaning condensate and other pollutants in the input line).

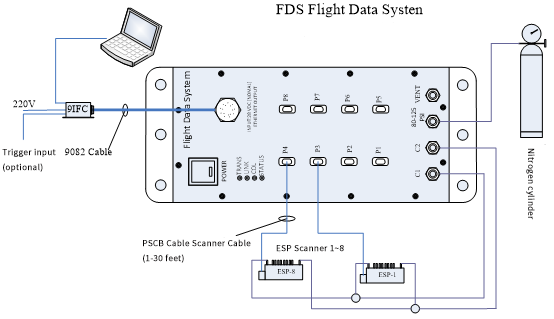

FDS Initium system

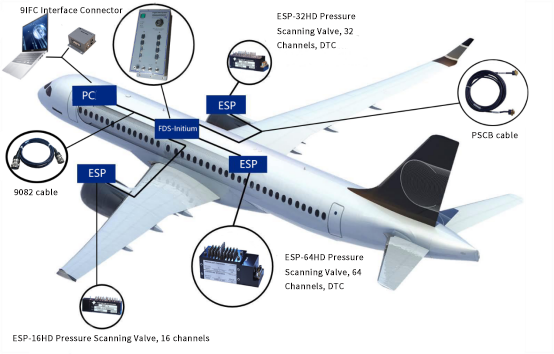

FDS Initium system provides up to 512 channels. Standard full-range pressures range from 5 "H20 to 150 psid. The FDS Initium data acquisition system is a DTC series small pressure scanning acquisition system. The FDS Initium system integrates analog circuit design with digital temperature compensation technology to maintain optimal accuracy without in-line range calibration. Ethernet-based systems directly connect to any combination of up to eight 16 -, 32 -, or 64-port DTC scanners, and multiple systems can be networked to meet larger measurement channel requirements.

The ESP pressure scanner is a miniature electronic differential pressure measurement device consisting of an array of silicon piezoresistive pressure sensors, one for each pressure port, mounted on a general-purpose hybrid ceramic substrate using proprietary technology to maximize long-term stability. Options include a cleaning capability isolated from the pressure sensor to remove moisture and contamination. Other options include digital temperature compensation technology, currently employed gen2 amplifier technology. Pressure measurement ranges from 10 "H2O to 150 PSI.

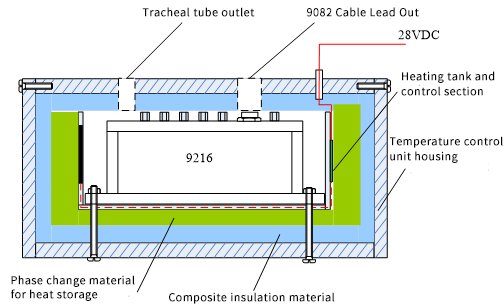

The ESP pressure scan valve can also be installed in an optional compact insulated thermal control unit, the heating tank. The heating tank has a heating circuit to regulate the temperature of the sensor to maintain thermal stability at extreme temperatures.

NetScanner 9216 pressure scanning valve

The Model 9216 Smart Pressure Scanner integrates 16 silicon piezoresistive pressure sensors with the latest microprocessor technology for any pressure range in a compact, rugged package. Each field replaceable pressure sensor includes a temperature sensor and EEPROM to store calibration data as well as sensor identification information such as pressure range, factory calibration date, and last or next calibration date managed by the user. The microprocessor also controls the actuation of the overall manifold to calibrate the zero or range online upon request. This function actually eliminates the sensor offset drift error so that the system accuracy error is less than ±0.05% FS. Pressure measurements range from 10 "H2O to 1100 PSI.

Ⅲ、Application examples

1. Our FDS-Initium model and ESP series pressure scan valves can meet the pressure measurement requirements of flight tests when there is enough space in the cabin or engine room. The FDS-Initium system uses the ESP series of pressure scanning valves. The scanner communicates directly to the user's host PC via TCP/IP or UDP, and the data is output in temperature-corrected engineering units. The connection required for system operation is simple, and the user can obtain or provide power using the 9IFC module, providing a convenient interface for power regulation, hardware triggers, and Ethernet communication. The ESP pressure scanning valve module is connected to the FDS-Initium host via 9082 cable.

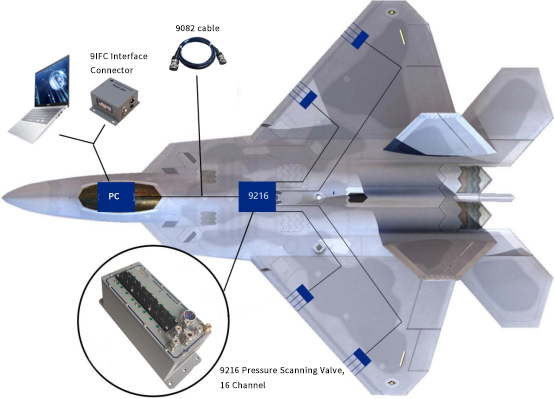

2. When the cabin space is limited and the collected pressure is large, our NetScanner series 9216 pressure scanning valve can meet the requirements of flight test pressure measurement. Type 9216 intelligent pressure scanning valve supports 16 pressure channels and automatically sets 10/100 Base-T Ethernet interface. The connection required for system operation is simple, the user can use the 9IFC interface connector power supply, the module is connected to the 9216 via 9082 cable, providing a convenient interface for power regulation, hardware triggers and Ethernet communication.